What are MOSH and MOAH?

Author Dr. Bettina Plaumann

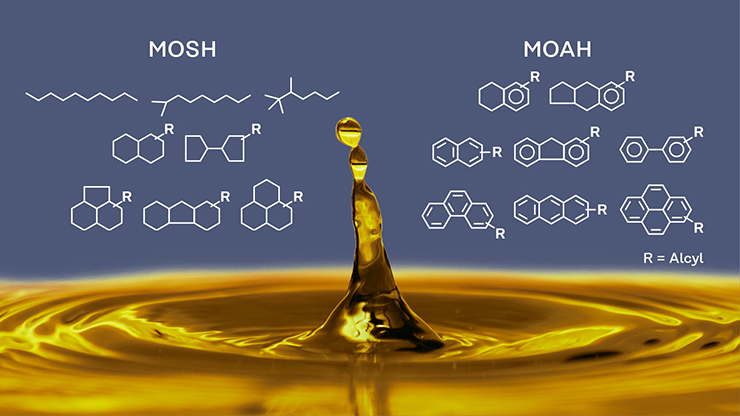

Mineral Oil Hydrocarbons (MOH) are chemical substances that can be found in mineral oil. They can contaminate food and are potentially toxic to humans. The two main types of MOH are:

- MOSH: Mineral Oil Saturated Hydrocarbons, which either directly stem from crude oil or form during the refining process. The MOSH fraction includes substances like paraffins.

- MOAH: Mineral Oil Aromatic Hydrocarbons, which can attach themselves to MOSH. They can account for up to 20% of the mineral oil composition. Even in saturated molecules, there is typically at least one aromatic ring present in the hydrocarbon molecule.

Low concentrations of MOSH and MOAH exist everywhere in the environment. In addition, various industrial processes can increase the presence of MOSH and MOAH in and around food.

It is not possible to keep all food completely free from MOSH and MOAH. Hence, it is important to form a differentiated understanding of these substances, their potential toxicity and countermeasures to minimize food contamination. This article is meant to provide an overview.

Why are MOSH and MOAH considered contaminants

MOSH is accused of causing liver damage and MOAH is potentially carcinogenic.

However, research on the toxicological effects of MOSH and MOAH on humans is still in its early stages. Based on initial studies, scientists believe that MOH can have long-term adverse effects on the central nervous system, promote pneumonitis, and cause eye and respiratory tract irritations.

Toxicological aspects of MOSH

When MOSH is taken in at a rate that is higher than its rather slow absorption and excretion, it can accumulate in the human body. In particular, fat cells, the liver and the lymphoid system are susceptible to this. Certain types of MOSH can cause inflammation in the liver and heart valves, as well as histiocytosis in lymph nodes.

However, the blanket statement that “all types of MOSH will cause liver damage” is wrong. It’s important to differentiate between two types of MOSH:

- Low-viscosity MOSH (small molecular size)

- High-viscosity MOSH (large molecular size)

These types of MOSH can be further characterized as follows:

| Viscosity | Molecular size | E.g. found in | Food contact | Health risk | |

| 1. | Low | Small | H1 lubricants | No | High |

| 2. | High | Large | 3H lubricants | Yes | Low |

Low-viscosity MOSH are potentially dangerous if ingested. They can be found in H1 lubricants for food producing equipment, among other things. H1 lubricants are made from technical white oils and they are not intended for food contact. If food contact occurs, the food should be disposed of. Regulators have posed very strict limits on the concentration of technical white oils in food.

According to Andreas Adam, the Chairman of the Food Grade Lubricants Working Group, the liver toxicity effects of low-viscosity MOSH were only observed in a certain species of rats, which some researchers suggest may be a “false positive” for humans.

High-viscosity MOSH can be found in 3H lubricants, for example. These lubricants are made from medicinal white oils. They are food additives, such as mold release agents, and intended for direct food contact. They pose a lower health risk compared to the previous group, but the upper limits are also strictly regulated.

MOSH: At a glance

- Minimal acute oral toxicity

- Non-carcinogenic

- Potentially tumor-promoting

- Potential inducer of microgranulomas in tissues

Toxicological aspects of MOAH

In terms of toxicology, MOAH should be divided in two subcategories, based on the amount of PAC (polycyclic aromatic compound) “rings”:

- MOAH with three or more PAC

- MOAH with one or two PAC

The former is potentially carcinogenic and genotoxic, while the latter is relatively harmless. According to Andreas Adam, MOAH with three or more PAC is present in crude oil, but gets removed from mineral oil in the refining process.

MOAH is absorbed by the human body, but does not bioaccumulate.

MOAH: At a glance

- Minimal acute oral toxicity

- Potentially carcinogenic

- Potentially genotoxic

- Of special concern: MOAH with 3 or more aromatic rings

Keep MOSH and MOAH out!

Do you need innovative, high-performance packaging materials that can help you drastically reduce MOSH and MOAH migration into food? Contact our packaging experts and ask for EVAL™ EVOH and KURARAY POVAL™.

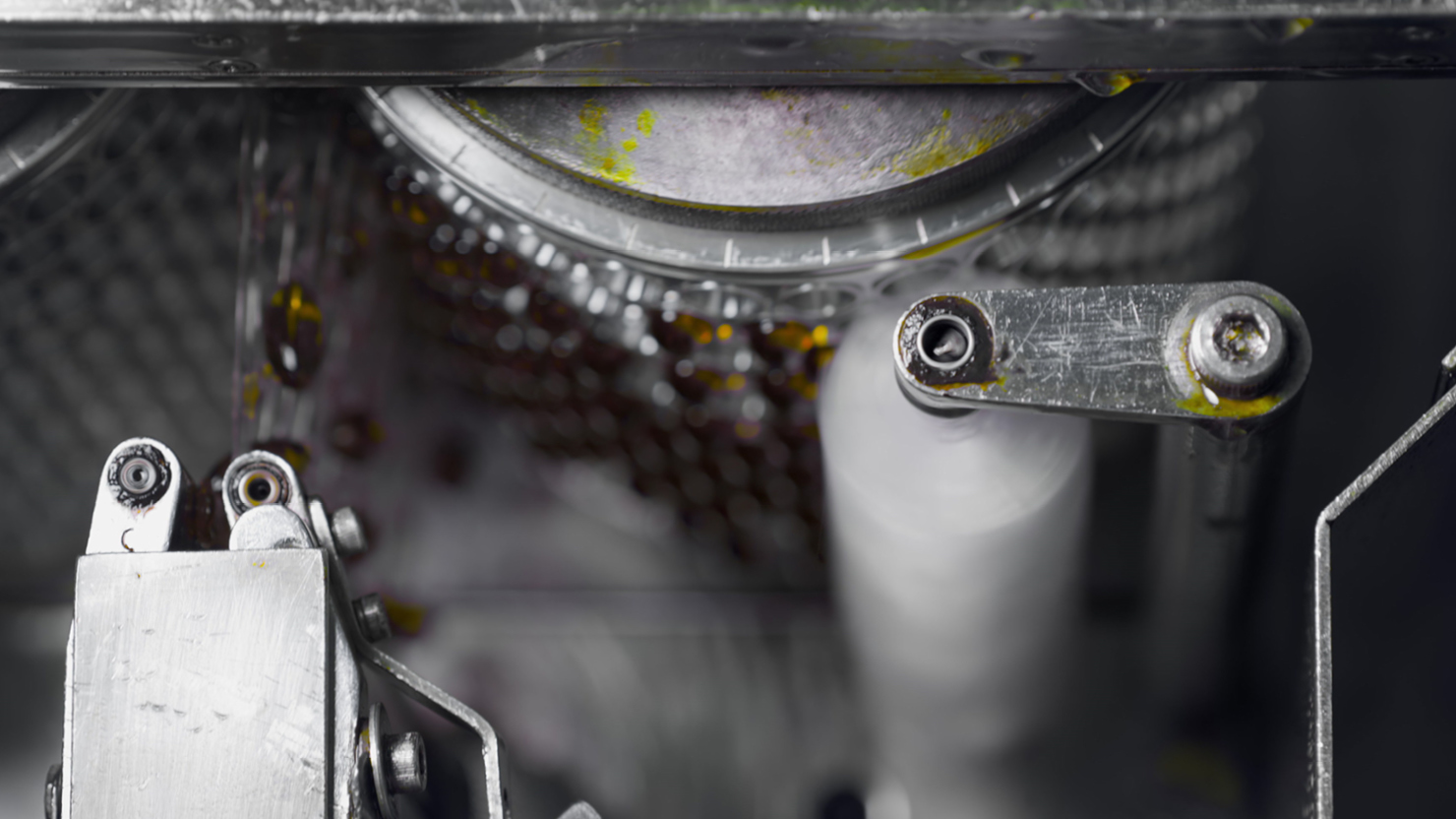

How do MOSH and MOAH enter our food?

Mineral oil hydrocarbons can enter our food in each step of the processing and production chain: Food raw materials can be exposed to industrial exhaust gases and emissions from energy suppliers. During harvesting, food can accidentally come into contact with oils that were used to lubricate farming equipment. MOSH and MOAH contamination can also happen during storage, transport or production. They can also stem from recycled packaging materials, printing inks or oil-treated gunnysacks that come into contact with food.

The main sources of contamination are:

Unintended:

- Printing inks

- Recycled cardboard

- Lubricants from food producing equipment (machine oils, hydraulic oils)

- Atmospheric gases

Targeted use:

- Adhesives

- Food additives (release agents, glazing agents)

- Plant protection products (paraffins)

Natural occurrence:

- Animal- or plant-based waxes

- Olefins in plant-based ingredients

Dry foods with a large surface area are particularly affected by contamination. This includes products such as rice, breakfast cereals, flour, black pepper or semolina.

Foods rich in fats, such as chocolate, butter, nuts and cooking oils, can also be subject to MOSH and MOAH contamination.

How are MOSH and MOAH regulated?

To date, there are no uniform legal limits. Within the EU, the EU General Food Law Regulation No. 178/2002 and the Framework Regulation (EU) No. 1935/2004 apply, which broadly state that unsafe food should not be placed on the market.

USA: Technical white oil limits

The US Food and Drug Administration (FDA) has set a maximum limit of 10 ppm for technical white oil. This particularly targets the harmful low-viscosity MOSH, e.g. found in the aforementioned H1 lubricants.

Germany: MOSH guidance values

The German Food Association (Lebensmittelverband Deutschland e. V.) and the Joint Federal Working Group on Consumer Health Protection (Länderarbeitsgemeinschaft gesundheitlicher Verbraucherschutz, LAV) have published guidance values for MOSH limits in certain product categories for the first time in April 2019.

| Product | MOSH limit in mg/kg of food |

| Fish & fresh products | 60 |

| Cereals | 15 |

| Vegetable oils | 13 |

| Confectionary | 9 |

| Bread & bakery products | 6 |

| Nuts | 4 |

German Printing Ink Ordinance (Druckfarbenverordnung)

In Germany, there is a printing ink regulation that all federal states approved in November 2021. There is a transitional period of four years. The centerpiece of this regulation is a positive list that enumerates all colorants and their maximum allowable amounts for safe use. To be included in the list, there must be sufficient toxicological data on the colorant’s health hazards.

German Mineral Oil Ordinance (Mineralölverordnung)

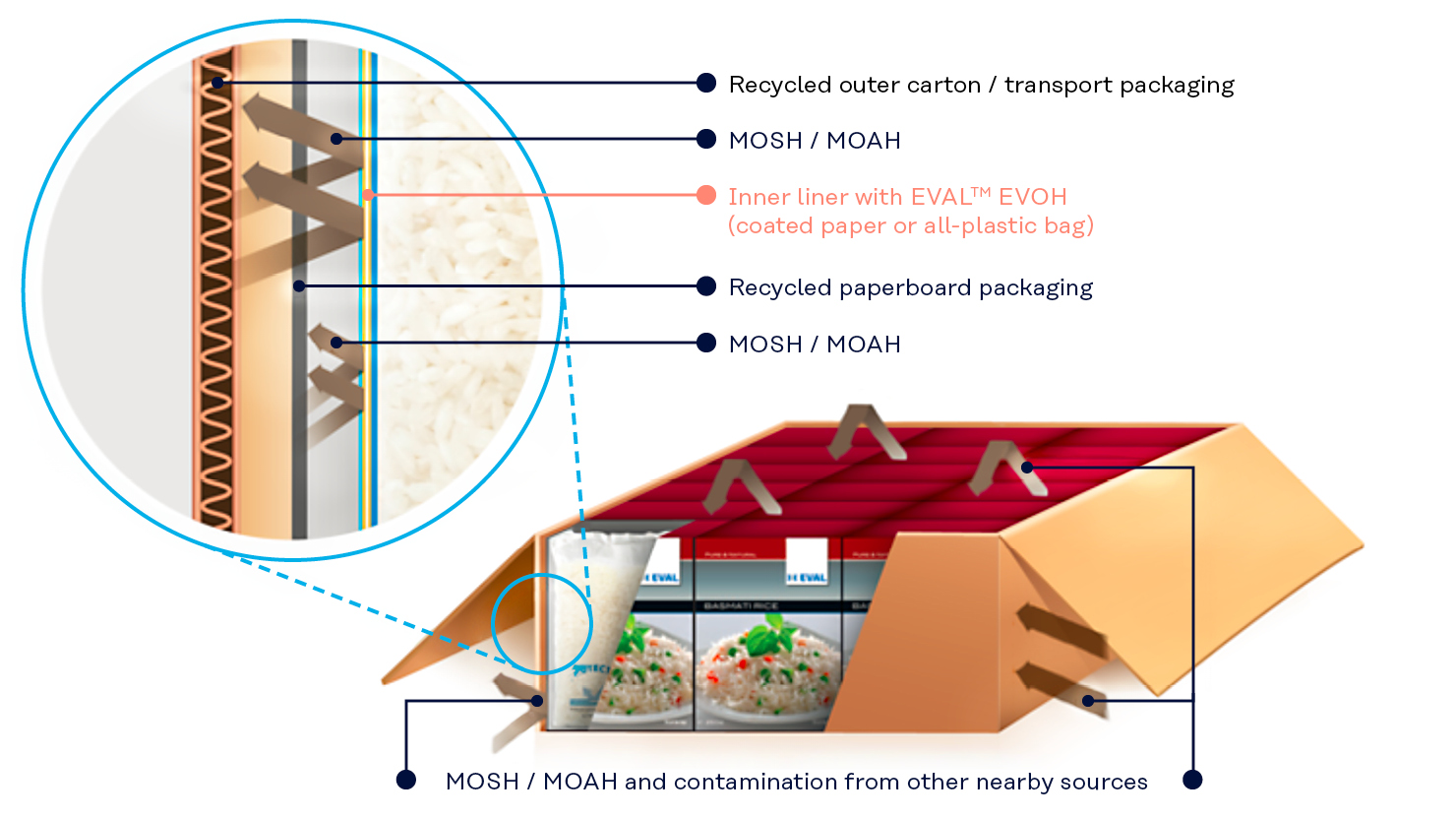

The German Mineral Oil Ordinance (Mineralölverordnung) aims to hinder the transfer of MOAH from recycled paper packaging into food. To achieve this, the regulation mandates the use of “functional barriers”. Aluminum, certain plastics like PET or PA and certain other materials are capable of forming such a functional barrier. The barrier may take be in the form of an additional layer or bag. Exceptions are possible under certain circumstances.

The ordinance establishes a MOAH detection limit of up to 0.5 mg/kg food. In other words, MOAH concentrations of less than 0.5 mg/kg are regarded as “undetectable”.

EU: MOAH guidance values

So far, there are only recommendations from European authorities regarding the transfer of MOAH to food. In April 2022, a committee of the European Union reached an agreement on the draft “Joint statement of the Member States regarding the presence of Mineral Oil Aromatic Hydrocarbons (MOAH) in food”.

The proposal includes a categorization of dry foods with a fat/oil content of up to 4%, where a limit of 0.5 mg/kg of MOAH would be permissible. For the second group of foods with a fat/oil content above this threshold, a limit of up to 1 mg/kg of MOAH would apply.

MOSH MOAH analysis

The analysis of MOSH and MOAH is very complex because it involves examining entire groups of substances rather than individual compounds. As a result, there is a high risk of confusion with similar substances. Currently, there is no standardized method for measuring the content of MOSH and MOAH in food. Generally, the analytical detection is done as a sum parameter.

However, some companies are exploring more differentiated methods of analysis. Since the toxicological properties of MOSH and MOAH depend on the viscosity (MOSH) and the amount of PAC (MOAH), further advances in MOSH MOAH testing are a high-priority research endeavor.

How can packaging protect food from MOSH and MOAH?

Kuraray is a specialty raw material supplier for plastic and paper packaging applications. Our materials, in conjunction with other packaging materials, can form a functional barrier that can effectively seal off MOSH and MOAH.

Food packaging with EVAL™ EVOH

Thin multilayer plastic structures containing just 3 µm of Kuraray EVAL™ EVOH can form a functional barrier to prevent MOSH/MOAH and other organic contaminants from migrating into food. These findings have been determined by the Food Safety Authority of the Canton of Zürich (CH) and confirmed by Fraunhofer (DE), as well as the University of Hasselt (BE).

EVAL™ EVOH offers excellent performance characteristics for a variety of packaging applications: It can be coated directly onto paperboard, coated or laminated onto paper to make a separate protective inner liner bag or used in full plastic packaging. EVAL™ EVOH offers a recyclable solution, as few microns of EVAL™ EVOH do not disrupt the polyolefin recycling streams.

Food packaging with Kuraray POVAL™/EXCEVAL™

KURARAY POVAL™ is the brand name for our polyvinyl alcohols (PVOH). These materials are hydrophilic, which makes them a suitable choice to form a barrier against grease and mineral oils such as MOSH and MOAH. Due to the hydrogen bonds between the polymer chains and the crystalline structure, KURARAY POVAL™ also forms an excellent barrier against oxygen. These materials offer high tensile strength and elasticity, as well as high chemical and thermal stability. KURARAY POVAL™ is FDA-approved for direct food contact.

EXCEVAL™ is the trade mark of our hydrophobically modified polyvinyl alcohol. It is used in food packaging applications that require high water resistance (e.g. DIN D3 level) in addition to other performance characteristics such as grease and oil barrier. The FDA-approved EXCEVAL™ can be coated on paper or used as a gap filler between paper pulp.